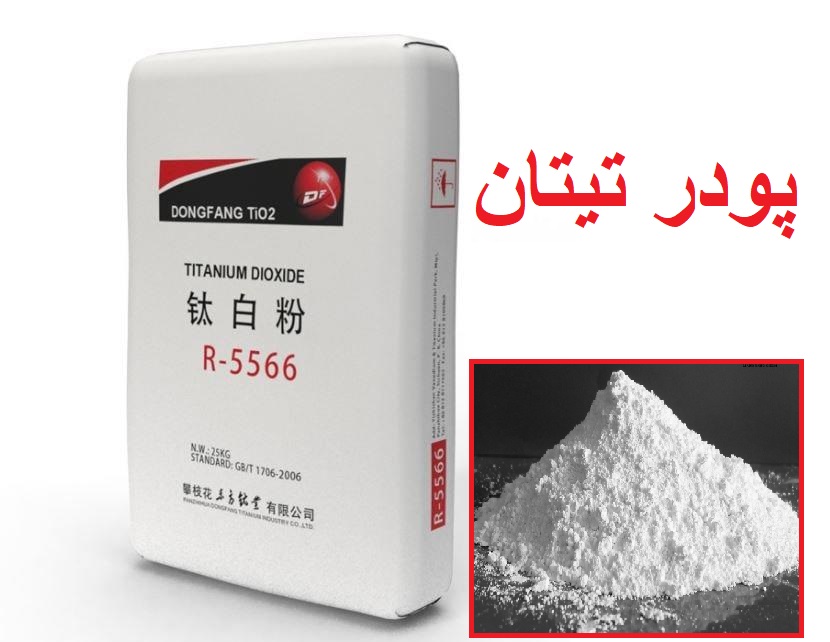

What is Titanium Powder 5566?

Titanium powder is white in color and does not burn. Titanium powder or titanium dioxide is a chemical compound and is difficult to dissolve in water. Titanium powder 5566 has a white pigment that has good covering power in paint, paper and plastic. Titanium powder 5566 is chemically neutral. In other words, it is not considered as a dangerous substance.

This material consists of titanium and oxygen elements. Titanium powder is one of the most widely used titanium compounds and is used in various industries as a pigment, absorbent, catalyst, and even in cosmetic and food products.

Features of Titanium Powder 5566

One of the distinctive features of Titanium Powder 5566 is its bright white color. It also repels UV rays due to its reflective properties. The general features of Titan are as follows:

- The amount of titanium dioxide: at least 93%

- Rutile content: at least 97%

- Density: 4

- Particle size: 3 micrometers

- Oil absorption rate: 18-23

- PH level: 6-9

Application of titanium powder

About 80% of titanium usage in the world belongs to its use in paint, enamel, paper and plastic. 8% of the use of titanium is used in fabric printing, fibers, rubber, cosmetics and even food. You can also find small amounts of titanium in glass ceramics, electrical ceramics, catalysts, electrical conductors, and even red candies.

Due to its unique properties, titanium is used as a raw material for white paint in the paint, paper, plastic and rubber industries. In general, polymer and plastic manufacturers who produce bright white products are more likely to buy titanium powder.

It is interesting to know that titanium also has medicinal uses. For example, they use it to heal skin burns. One of the characteristics of titanium is that it reflects the ultraviolet rays of the sun. Therefore, it is seen in the composition of sunscreen and anti-burn creams. It is also used to make the coating of pharmaceutical tablets and capsules.

They use titanium in the allowed amount in food. For example, in processed cheeses and cakes and pastries. Also, they use titanium in food packaging to prevent the material from spoiling.

How to use Titanium Powder 5566?

Parts that are made with polyester resin and do not use titanium, after a long time, cracks will appear on these parts due to environmental conditions. To prevent cracks in the mold and part, titanium is added to the resin.

The way to add is that after combining polyester resin and cobalt naphthalate or accelerator, you can add titanium to the composition in the amount of 2 to 3% of the volume of the resin; And stir regularly until the seeds are completely dissolved and the resin mixture is uniform.

If you use titanium in the resin, you should know that your resin will turn white because of the titanium pigment.

Buying Titanium Powder 5566 from Shimi Afsoon

Titanium Powder 5566 is one of the popular products of Shimi Afsoon Company, which is used in various industries such as coating, plastic injection and paint production. This powder can be used for many industrial applications with properties such as heat resistance and increasing the hardness and beauty of the surface.

Buying Titanium Powder 5566 from Shimi Afsoon Company assures you that you will receive a high quality and original product. Therefore, if you are looking for a quality and reliable material, buying Titanium Powder 5566 from Shimi Afsoon can be a good option.

The price of Titanium Powder 5566

Exchange rate fluctuations and many parameters affect the price of titanium powder daily. The first parameter is the global selling price of titanium powder. The price of Titanium Powder 5566 varies depending on the purchase amount and the type of packaging. Shimi Afsoon has always tried to keep the price of titanium powder cheaper than the market price in addition to maintaining the quality of its products.

Packaging and distribution

Titanium Powder 5566 is packed in 25 kg bags.

Safety and maintenance of Titanium Powder 5566

Considering that Titanium Powder 5566 is non-toxic and dangerous, it is recommended to use gloves, glasses, safety shoes and a mask while working. Also, if titanium comes into contact with eyes or mouth, wash it immediately with water. Inhalation of Titanium Powder 5566 dust during transportation may be harmful to health.

Learn more about titanium powder

Titanium production methods

Titanium is one of the most important and expensive metals, which is limited worldwide due to technical and economic problems. In the following, we will mention some methods of titanium production:

- Caprolite chloride method: In this method, first titanium oxide along with carbon and chlorine are entered into the furnace at a high temperature to produce titanium tetrachloride (TiCl4) and carbon dioxide. Titanium tetrachloride is then reacted with a gas such as methanol in tanks where temperature and pressure are controlled to obtain metallic titanium.

- Metal detection method: In this method, titanium oxide is placed in a furnace with a base metal such as magnesium or calcium at high temperature and in the presence of a gas such as argon. In this process, titanium oxide reacts with the base metal and metallic titanium is obtained.

- Electrometallurgy method: In this method, titanium oxide is placed in an electrolysis cell along with an electrolyte. By applying an electric current, metallic titanium is obtained.

- Direct reduction method: In this method, titanium oxide reacts together with a carbon compound such as carbon to produce metallic titanium at high temperature and high pressure. This process is often carried out in induction furnaces with high temperatures and produces high purity titanium with suitable properties for use in many industries.

Methods of producing Titanium Powder 5566

- Plasma arc process: In this method, titanium is placed in a gas environment at a high temperature, which leads to plasma production of hydrogen and argon gases. This plasma produces titanium powder with very small particle size.

- Mechanical grinding process: In this method, titanium is placed in a grinding machine along with an oxidizing compound, such as aluminum oxide. This process breaks down the titanium into very fine particles.

- Hydrogenation method: In this method, titanium is placed at a high temperature along with a hydrogen compound, such as titanium hydride. In this process, hydrogen reduces titanium compounds and titanium powder with very fine particle size is produced.

- Electrochemical method: In this method, titanium is placed together with an electrolyte in an electrolysis cell. In this process, titanium is measured as an electrode and by applying electric current, it is produced as titanium powder with very small particle size.