What is GBS Aerosil?

GBS Aerosil is a powdered hydrophilic fumed silica that has high transparency and is introduced as the most famous and best brand of Aerosil . Aerosil GBS is used as a concentration agent and to prevent sedimentation.

Application of Aerosil GBS

- Paints and coatings

- Unsaturated polyester resin, lamination resins and coating gel

- Glue and seal

- Printing ink: cable compounds and cable gel

- Plant protection

- Skin care (face care, facial cleansing, body care, baby care)

- Decorative cosmetics / make-up

- Sanitary ware (shower and bath, oral care…)

- Hair care (shampoo, conditioner and conditioner)

- Mineral-based silica and silicate thickeners and stabilizers

Complications of GBS Aerosil

Research has shown that contact with Erosil does not cause eye or skin irritation; But chronic skin contact with this aerosil may cause degenerative eczema or dryness. Of course, these reactions can be avoided with extreme care or protection of the skin.

Properties of Aerosil GBS

Aerosil is widely used in various industries such as ceramics, composites, fiberglass, paints, concrete lubricants, sculptures, etc. Also, Aerozil has a polishing property and in terms of softness, it also has a volumizing property.

Advantages of GBS

- Silicone elastomer filler

- Viscosity regulator in paints, coatings, printing inks, adhesives and polyester resins.

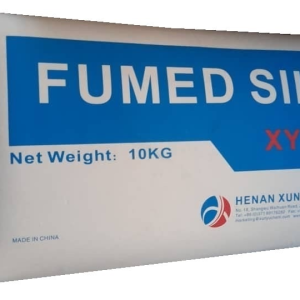

GBS Aerosil packaging

GBS is supplied to customers in multilayered 10 kg bags. It is better to keep this product in closed containers under dry conditions. Aerosil GBS should be used within 2 years of production.