Polyurethane wood foam

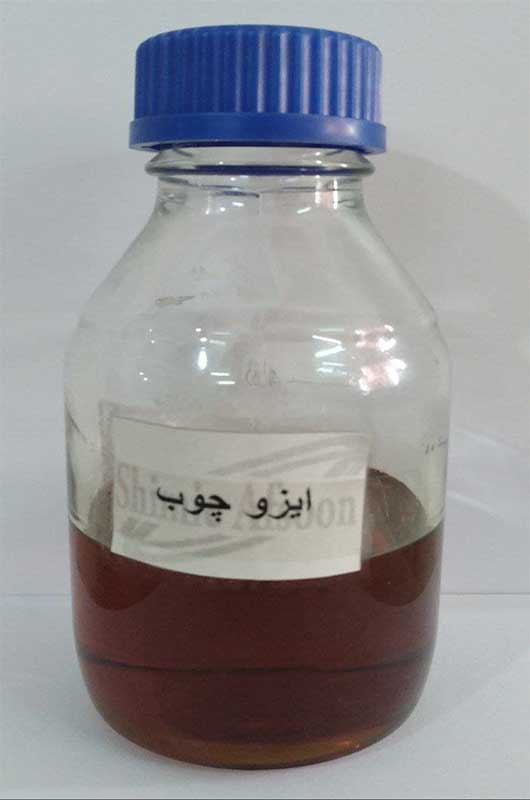

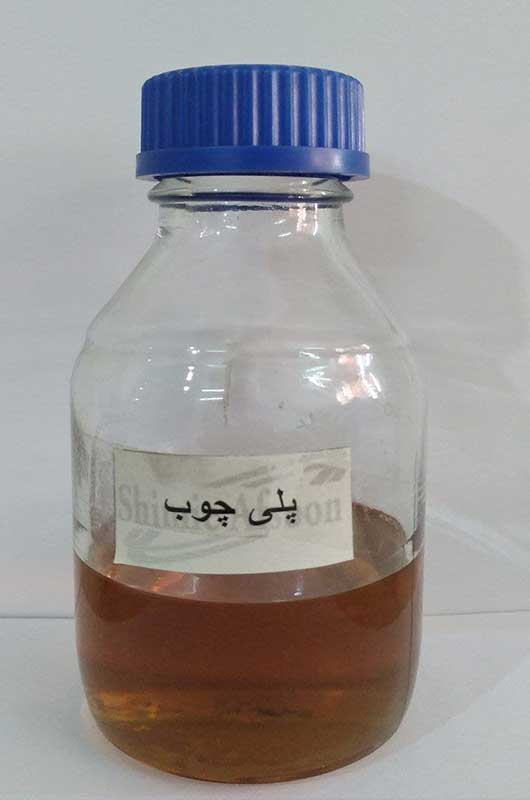

Due to the expansion of urban life and the destruction of trees and the environment, today instead of using wood in the decoration industry, they use polyurethane wood foam. Polyurethane wood foam, which is called artificial wood in the market, is made from a combination of polyol (resin) and isocyanate (hardener).

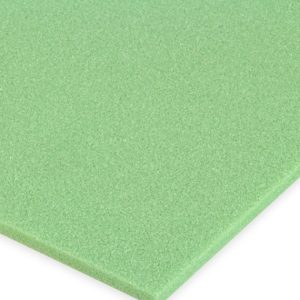

After a period of time has passed from the combination of these two components (polywood and isowood), the material begins to increase in volume or, in popular terms, puffs up and becomes a hard object like wood. The degree of hardness, resistance and increase in volume can be changed depending on the ratio of densities that exist.

In Iran, hard polyurethane foam is called wood foam in short, and it is known as Wood Imitation Polyurethane Foam in international markets. In general, wood foam is produced by both manual and machine methods.

Polyurethane wood foam

Advantages of polyurethane wood

Polyurethane wood foam is used in furniture, decoration and model making industry. The first component of the polyurethane system is the first layer, which must be stirred very well before use so that it becomes a uniform cream or milky color. This mixing is very important in ease of use, beauty and results. The second component of the isocyanate polyurethane system has a darker color than the first poly and maintains its darkness when combined.

The ratio of the combination of isocyanate and polyol is 1:1 and it is necessary to use an accurate scale to measure the ratios.

The best temperature for the combination of isocyanate and polyol is between 20 and 25 degrees, and the high and low temperature is directly related to the reaction speed. The lower the temperature, the longer the drying speed of the piece, and the higher the temperature, the faster the drying speed.

After mixing and pouring the ingredients into the mold, it takes 5 to 8 minutes to remove the piece from the silicone mold and keep it on a flat surface until it dries.

The temperature of the part during drying in the mold reaches about 90 to 95 degrees, which is the advantage of chemical enchantment polyurethane wood foam that increases the depth of the silicone mold by 2 to 3 times.

Other advantages of wood polyurethane include manual use, resistance and durability of the product, the ability to sand and putty, machining, drilling, the ability to hammer nails and staples, screwing without cracking, adhesion with instant adhesives, excellent color tolerance, and most importantly, resistance against pests and insects and preventing cutting down trees.

Application of polyurethane wood foam

Polyurethane wood foam is widely used and is known as the best alternative to wooden items and parts due to its many advantages. Among the uses and applications of polyurethane wood foam, the following can be mentioned:

– Furniture making

– Sculpting

– Building industry

– Making wooden items and parts

– Decorative goods such as paintings, mirror frames and photo frames

– The parts that are used in turning to make molds

– Car interior design

– Shoe mold

Polyurethane foam production method

To produce wood polyurethane foam, we first reduce the moisture content of the poly to zero, then mix the poly with ISO and mix it with a high-speed stirrer, the material must be spread on the surface of the mold. It has a density of 500 to 550 with a 15 to 25 percent increase in volume.

Advantages of polyurethane wood foam

- Light weight

- Low and affordable maintenance cost

- Wood foam is waterproof, fireproof and rustproof

- Acoustic properties

- No need for additional glue for connection

- Long life span

- Similarity to natural wood

- Products made with wood foam are easy to cut

- Simple and fast production process

- High mechanical properties

- No water absorption

- Excellent surface and appearance

Features of polyurethane wood foam

The most important feature to consider in wood polyurethane foam is its density. According to the expected physical and mechanical properties of polyurethane wood foam, companies producing raw materials set the density of this type of foam between 60 and 700 kg/m3. It should be noted that with the increase in density, the physical and mechanical properties increase, and on the other hand, the weight of the produced parts will also increase.

Important points regarding the use of polyurethane wood foam

- Material consumption temperature: 23-25 degrees Celsius

- Mold temperature: 45-55 degrees Celsius

- Weight ratio of polyol to isocyanate: 100 to (80 to 110)

- Cream time: 40-50 seconds

- Growth completion time: 180 seconds

- Free foam density: 60-700 kg/m3

- Molding time: 5-15 minutes

Polyurethane wood foam packaging

To buy the best quality polyurethane wood foam in 470 kg barrels, you can get guidance from Shimi Afsoon sales advisors. The shelf life of polyurethane wood foam is 9 months.

Sale price of polyurethane wood foam

For more information about the purchase and price of guaranteed quality polyurethane wood foam and how to order, please contact our colleagues at the Shimi Afsoon sales unit.