Introducing RTV2 mold making silicone

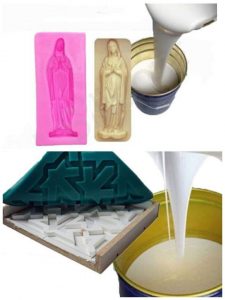

RTV2 mold making silicone is a room temperature silicone rubber. RTV silicone is available in the market as a one-component product or a combination of two-component mixtures. Manufacturers produce RTV silicones in the soft to medium range in terms of hardness.

RTV2 mold making silicone is a non-sticky and flexible material. When you want to make a resin piece, you should actually pour the resin solution into a non-stick mold so that it can be easily removed from the mold after drying. Therefore, the mold must be flexible.

RTV2 silicone only adheres to silicone and not to any other material. RTV2 silicone is not only used for resin products and is also used in industry and for plaster parts. Also, one of the features of this product is that it can withstand temperatures above 200 degrees Celsius.

Application of RTV2 mold making silicone

As mentioned, you can use this product to mold different shapes. It is used in sculpting, construction industry and tampography.

You can also make a mold for products made of Polyurethane wood foam, concrete, resin, and GRT, and silicone molds do not stick to these products.

RTV2 silicone is also used for materials that need to be molded with wax and products that are made of stone.

It is also used in candle making and lighting industry, stationery and handicrafts.

Features of RTV2 mold making silicone

- RTV2 silicone is very easy to use.

- It has medium hardness and good flexibility.

- It has high tensile strength.

- It can be easily duplicated from the mold in large numbers.

- It is a good insulator for water, air and sound.

- It has the property of electrical non-conductivity.

- It is odorless.

Important points regarding the use of RTV2 mold making silicone

RTV2 mold making silicone becomes a flexible and non-sticky elastomer as a result of reaction with the hardener. Usually, between 2 to 3 percent of catalyst is required to make a silicone mold.

No matter what attributes the target piece has, it can be seen exactly in the silicone mold. So, make sure that the target object is clean and free of dust and pollution before molding.

After you have prepared the mold, mix the silicone and hardener in the proper ratio accurately and mix well for about 7 minutes. Then place the mixture for 5 minutes in an environment where there is no air or as it is called “vacuum environment” so that the bubbles that are formed inside it disappear.

The capacity of the container in which you mix the ingredients must be two or three times the volume of silicone and hardener because it produces so much foam when mixing. After pouring the silicone and hardener into the mold, you must wait 24 hours for it to harden well. The appealing feature of RTV2 mold making silicone code 3335 is that it requires less drying time (between 3 and 5 hours).

RTV2 mold making silicone packaging

5 kilograms packaging

10 kilograms packaging

25 kilograms packaging

RTV2 mold making silicone durability

The RTV2 mold making silicon’s shelf life is one year