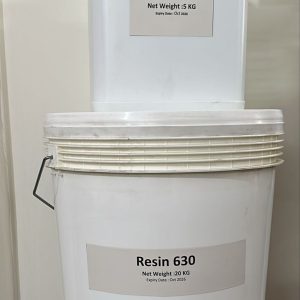

Equivalent to epoxy glue 106

Due to its very favorable mechanical properties and very high strength and very high adhesion strength, it is widely used in the aviation industry of the country and for gluing composite to composite, composite to metal, metal to metal, aluminum to aluminum, metal to wood.

The percentage of the combination of glue and hardener in the equivalent of epoxy glue is 106 = one kilo of resin and 800 grams of hardener.

It can withstand a temperature of 120 degrees.

What is Epoxy Glue?

Epoxy resin glue is a type of glue that is made based on epoxy resins. This type of glue is formed by combining two different materials or components, a resin and a material that acts as a hardener or catalyst. Epoxy resin glue has features such as high mechanical strength, heat resistance, chemical corrosion resistance and very strong adhesion. These features make this type of glue to be used in various applications such as industrial repairs, construction, automobiles, artworks and electronic industries.

In the process of using epoxy resin glue, two different components are measured separately and then mixed. The curing agent then begins chemical action and binds the epoxy resin as a solid matrix. This process usually results in the formation of an adhesive with strong mechanical and chemical properties that can be used in a variety of applications.

In addition, their strong ability to withstand constant weight or force over a long period of time, as well as their outstanding resistance to physical and chemical influences, make two-part epoxies a very stable product that is very versatile and can be used for bonding, sealing, coating and Encapsulation can be used in many industries including electronics, medical equipment and aerospace.

Special formulations are also flame resistant, cryogenic serviceability, quick curing, high temperature resistant, etc.

When considering the effectiveness of an epoxy glue, it is helpful to analyze the general formula of its constituent compounds. Epoxies are created by polymerization of a mixture of two primary compounds, resin and hardener. When the resin is mixed with a specific catalyst, curing begins. Annealing is a process in which molecular chains react at chemically active sites, resulting in an exothermic reaction. The covalent bonds between the epoxide resin groups and the hardening amine groups (catalyst) that arise from this compound allow cross-linking of the polymer and, as a result, create the rigidity and strength of the epoxy.

Monitoring the curing conditions by temperature and choosing resin and hardener compounds allows changing the properties of mechanical resistance and thermal, electrical and chemical resistance; Therefore, epoxy glues have been developed to suit a wide range of applications and different operating conditions.

Epoxy resin glues adhere to a wide variety of materials, and their properties depend on the specific chemistry of the system and the nature of the crosslinking present. Some of the most important performance requirements include exceptional chemical and thermal resistance, excellent adhesion and water resistance, as well as satisfactory mechanical and electrical insulation properties.

Properties of Epoxy Glue

This adhesive has a very high resistance against harsh conditions and has the ability to stick to different types of surfaces. Also, this adhesive is able to fill small gaps and gaps that cannot be filled with other adhesives. This adhesive can be easily used on dry and wet surfaces and has high flexibility for surfaces that are subject to movement and deformation.

This adhesive can be used for various projects including industrial, construction and art.

What is epoxy resin glue and what are its uses?

Epoxy glue is a two-part glue that is formed when epoxy resin and hardener are mixed. The two ingredients are stored in separate containers and only mixed together when you are ready to glue – for example, you can do this using a double syringe. You must keep the mixing ratio 1:1, otherwise the resin will not bond.

Epoxy is very versatile and very strong, as well as a gap filler. Additionally, epoxy can be sanded, drilled and painted.

Types of epoxy resin glue

– Epoxy glue is used to glue metal materials together. This adhesive is very suitable for bonding metals such as aluminum, steel, copper, brass, etc.

– Epoxy glue is used to glue objects and materials such as plastic, polystyrene and polycarbonate.

– Epoxy glue is used in the construction industry to glue concrete blocks and install insulating materials.

– Epoxy glue is used for gluing ceramic tiles to the wall and different surfaces.

– In arts and crafts, epoxy glue can also be used to create handmade objects and decorations.

Advantages of using Epoxy Glue

-Very high resistance to harsh conditions

-Ability to stick to different types of surfaces

-Ability to fill small gaps and gaps that cannot be filled by other adhesives

-This glue can be easily used on dry and wet surfaces

-High flexibility for surfaces that are subject to movement and deformation

-Can be used for various projects including industrial, construction and art

Disadvantages of Epoxy Glues

Although epoxy glue has many positive features, it also has some disadvantages. Some of the disadvantages of this adhesive are:

- Long drying time that requires patience.

- To use epoxy glue, you must make sure that the surface to be glued on is completely clean and dry. You should also use enough glue to do its job well.

- Epoxy glue is very hard to remove and if it gets on your skin, it will be difficult to remove.

- For this reason, it is recommended to use medical gloves when using this glue.

- This glue causes skin sensitivity in some people. If you feel skin sensitivity when using this glue, you should quickly wash the skin with soap and water.

Instructions for epoxies

Roughen the surfaces you want to glue with sandpaper or smooth out the areas with a fine file. Remove dust, grease and dirt from surfaces.

Cut the end of the syringe. Turn the syringe up and squeeze the syringe gently and push the air bubbles up.

On a disposable surface, press the double plunger to dispense equal parts of resin and hardener. If your epoxy doesn’t have a tray, it’s a good idea to buy one. If you don’t have time to buy a tray, use a disposable plate.

Mix the resin and hardener quickly until thoroughly mixed (1-2 minutes).

Add a small amount of epoxy glue to the items you are gluing, carefully gather them and press them together firmly. Setting and baking times vary for different products, so check the package or manufacturer’s instructions for details.

Epoxy glue for metal

Using epoxy to bond metal is a useful alternative to welding, soldering, or bolting. A very strong epoxy for metal is the metal/concrete epoxy glue. This product is ideal for repairing appliances, machinery and pipes and is also very effective in tightening screws in metal.

Epoxy resin glue for cement

If you have cracks in your garden stepping stones, you can easily fix them with the right epoxy. When choosing your epoxy, consider the complexity and specific requirements of your project. Sometimes you will need epoxy glue to repair, fill and restore all kinds of concrete surfaces. If you need to bond concrete, metal/concrete epoxy resin adhesive is a good option. In addition to being water and impact resistant, this epoxy turns into a metallic gray color that in many cases does not require painting.

Epoxy resin glue for plastic

From lawn chairs to auto parts, plastics come in all shapes and sizes. With all the plastic products in most households, it’s no surprise that some of them need to be repaired from time to time. It’s a good idea to have an epoxy glue on hand that is specifically formulated for bonding and repairing plastic surfaces.

The PVC pipe under your sink has burst?!

Epoxy glue can be applied to wet surfaces and dried under water. It can be used in addition to plastic for surfaces such as wood, brick, ceramic, metal and concrete.

Marine grade epoxy resin glue

If your boat has a leak, use Loctite marine epoxy to keep it afloat. This advanced technology marine grade epoxy glue allows for underwater and curing applications. It’s incredibly strong and extremely versatile, making it a great tool for surfaces that are constantly submerged in water. This marine epoxy resin can be used on PVC, many metals, ceramics, fiberglass, concrete, glass, wood and certain plastics.

Properties and different applications of epoxy glue

Epoxy glue is one of the most widely used types of glue, which is used for different types of surfaces due to its special features. In the following, we will introduce and explain the various properties and uses of epoxy glue:

Iron and metal epoxy glue: This type of epoxy glue is suitable for gluing heavy metals and iron. Due to its characteristics, after drying, this type of glue has the capability of high impact and pressure resistance.

Fiberglass epoxy glue: This type of epoxy glue is suitable for gluing different types of fiberglass, composite and metals. The properties of this type of glue include high resistance to corrosion, heat and humidity.

Plastic epoxy glue: This type of epoxy glue is suitable for gluing different types of plastics, metals and wood. Due to its properties, this type of glue has a high resistance to impact, water, pressure and heat after drying.

Concrete epoxy glue: This type of epoxy glue is suitable for gluing different types of concrete and stones. The properties of this type of epoxy adhesive include high resistance to corrosion, pressure and heat.

Fiberglass epoxy glue: Fiberglass epoxy glue is a type of epoxy glue that is reinforced with glass fibers. This type of glue is generally used in projects due to the need for high strength. With glass fibers, this type of epoxy glue has a higher resistance to stress and bending.

Also, fiberglass epoxy glue has high resistance to heat and flame. This type of glue is very suitable for repairing and strengthening metal, plastic and wooden parts.

Plastic epoxy glue: Plastic epoxy glue is one of the types of epoxy glue used to connect plastic parts. This type of glue has characteristics such as high resistance to heat and flame, resistance to stress and bending, and resistance to chemicals. In addition, epoxy plastic glue has the ability to replace plastic welding.

Epoxy stone glue: Epoxy stone glue is used to repair and connect stone surfaces. These adhesives have two parts that combine when used. The first part consists of epoxy resin, which has characteristics such as high resistance to heat, impact and shock, resistance to chemicals, and resistance to moisture.

The second part contains the activator, which is used to fully combine with the epoxy resin. This type of glue is widely used as an effective and efficient solution for repairing and connecting stone surfaces.

Stone epoxy glue is one of the best options for gluing stones together or to other surfaces due to its high mechanical properties and heat and chemical resistance.

Paste epoxy glue: Using paste epoxy glue is very effective for repairing and connecting two pieces together. These types of adhesives are available in two types of packaging:

* Two-part packaging

* One-part packaging

In the two-part package, the epoxy resin and the activator are separate and must be mixed together at the time of use.

But in a one-part package, the epoxy glue is a ready-to-use paste that only requires applying pressure to join the two pieces together.

Paste epoxy glue is identified as a solvent-free material due to its properties such as shock resistance, heat resistance, moisture resistance and resistance to solvents.

Conclusion

Epoxy glue is one of the most widely used types of glue, which is used in various industries and many applications. This adhesive has very positive features such as high resistance to heat and pressure, the ability to fill small cracks and gaps that cannot be filled with other adhesives, high flexibility and easy to use. But like many other products, epoxy adhesive it also has disadvantages that should be considered.

When using this glue, you should be careful and pay attention to points such as using medical gloves and cleaning the surface before use.