Introduction of Casting Epoxy Resin 100

Casting Epoxy Resin 100 is a two-component, very transparent solvent that can be used for casting thicknesses of 5 to 7 cm for all layers on an average of 20 degrees, suitable for all decorative applications, such as furniture transparent epoxy table, wood coating, cube used in epoxy resin, LED electrical system coating, jewellery gift, etc.

Application of Casting Epoxy Resin 100

- Extremely transparent view

- It has no yellowness

- Crystal shine

- Has additional UV

- Without any air bubbles

- Amazing power

- Excellent surface smoothness

Casting Epoxy Resin 100 features

In high modulus unfilled epoxy systems, the curing agent must be selected according to the application. Baking at room temperature plus post-baking at moderate temperatures (50-60°C) gives high performance. Further stabilization at higher temperatures improves the thermal resistance of the part

Solid volume: 100% at 10-20 degrees Celsius

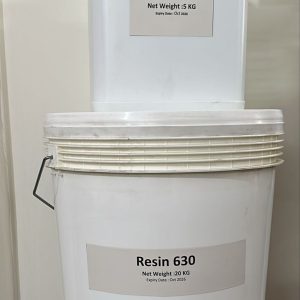

Casting Epoxy Resin 100 packaging

Resin: 10 kg

Hardener 5 kg

Durability of Casting Epoxy Resin 100

One year

Properties of Casting Epoxy Resin 100

- Product code 100

- Physical state of liquid

- UV transparent color

- Viscosity: 1.200 – 1.800

- Gelling time: 240 minutes

- Drying time: 24 to 36 hours

- Hardener composition percentage: 50%

- Pouring resin from a distance of 5 to 7 cm on the product