What is Ilkester PV 300 vinyl ester resin?

Vinyl ester resin is a type of plastic resin that is obtained by combining the polymerization of vinyl esters with polymer resin. Vinyl esters are a group of chemical compounds that have an ester group (-COO-) in their structure and are usually obtained from fatty acids. Vinyl ester resin is used in various industries due to its properties such as chemical resistance, heat resistance and flexibility.

Its applications include the production of various plastic artifacts, industrial components, food and pharmaceutical packaging, reinforced rubber materials, and corrosion-resistant coatings.

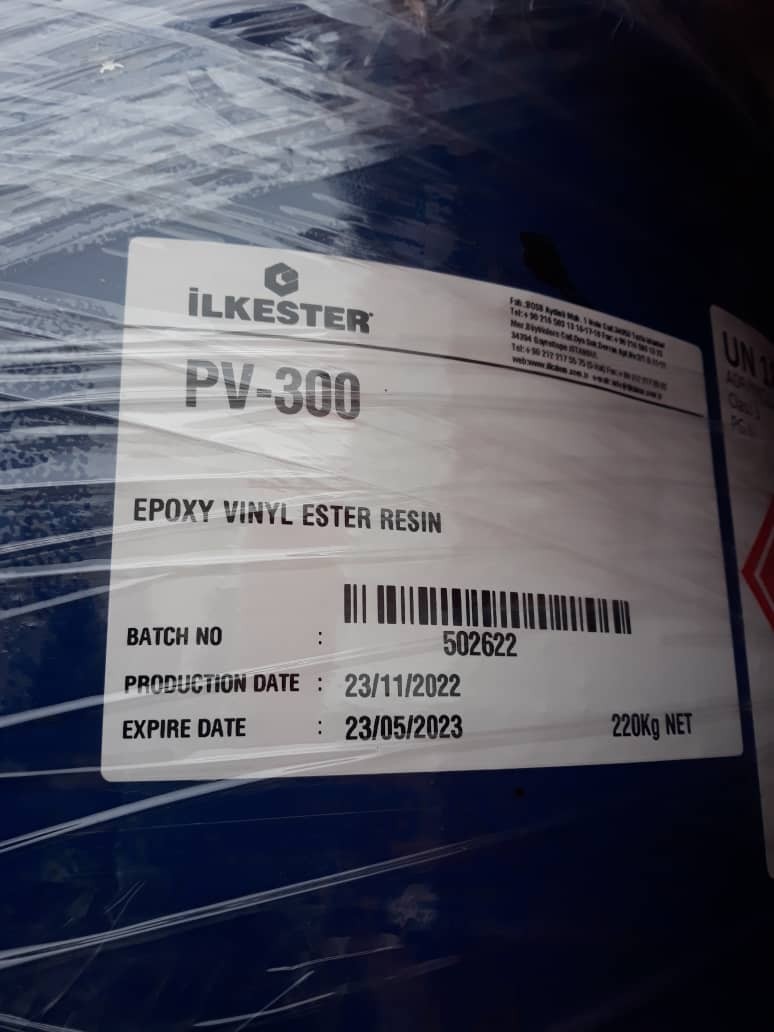

Specifications of Ilkester PV 300 vinyl ester resin

Ilkester PV 300 vinyl ester resin is an epoxy vinyl ester resin based on bisphenol A. Ilkester PV 300 vinyl ester resin shows corrosion resistance in a wide range of acidic and alkaline environments. When exposed to high temperatures or different thermal environments, PV-300 does not have serious losses in mechanical properties.

Application of Ilkester PV 300 vinyl ester resin

Ilkester PV 300 vinyl ester resin has high mechanical resistance values, it is used in the production of industrial storage tanks and process equipment. PV 300 also has good osmosis resistance. Due to its high water resistance, PV 300 is widely used in the production of marine vehicles and swimming pools as a skin resin and main laminate.

Vinyl ester resin with a certain thickness that is in the range of 20 to 40 mm is used as a surface coating. Ilkester vinyl ester is also solidly coated, which provides the best protection against various elements. This resin has high resistance to corrosion and acid effects, which is suitable for use in tanks, high temperature equipment, concrete, trenches and hand wells.

This resin prevents sliding and penetration of liquids to the bottom surface. Due to its resistance to corrosion and chemical effects, vinyl ester resin has the ability to create high resistance to chemical agents. This resin has high resistance to tearing and scratching in light traffic conditions.

Vinyl ester resin works well as a second coating in some cases and provides a useful application. This resin can be used to cover electronic parts, oil and gas industries, chemical industry equipment and water treatment equipment.

Application of Ilkester PV 300 vinyl ester resin

Applications of vinyl ester resin include coating of steel and concrete structures, electrical equipment, television and antenna, fishing boats, ships, marine vessels, fiberglass, canal and piping, chemical tankers and fuel tanks. This resin can be a suitable replacement for metals and unsaturated polyester resin based on FRP in applications where corrosion resistance is important.

Vinyl ester resin is used as a coating in the following cases:

Concrete and metal structures: vinyl ester resin is used to protect concrete and metal structures against chemical, thermal and mechanical attacks. This coating is able to protect surfaces against corrosion, acids, alkalis and other chemicals.

Tanks and industrial equipment: Ilkester vinyl ester is used to cover tanks, ducts, pipes, chimneys and other industrial equipment. This coating is mainly used to protect against chemical corrosion, abrasion, heat and pressure.

Industrial facilities: In industrial facilities, which may be in contact with chemicals, acids, alkalis and solvents in different concentrations, vinyl ester resin is used as a coating. This coating provides high resistance to chemical corrosion and protects the facility from chemical damage.

Protection of floors, tanks and walls: The use of Ilkester vinyl ester for protection of floors, tanks and walls is of great importance. This coating can minimize maintenance costs, increase the lifespan of structures and provide proper protection against various damages such as corrosion and wear.

By using Ilkester vinyl ester as a surface coating, you can take advantage of its features and benefits in various cases, including oil and gas industries, chemical industries, water treatment and electronic components.

Glass fibers can be reinforced by using vinyl ester resin coating. This process, known as “fiber reinforcement” or “composite reinforcement”, refers to combining glass fibers with vinyl ester resin and then stabilizing them with a vinyl ester resin matrix.

This method increases the resistance of glass fibers against destructive factors. Glass fibers alone are relatively weak, but by reinforcing them with vinyl ester resin, the compressive strength, bending strength, and resistance to corrosion and mechanical damage can be improved.

Important points of Ilkester PV 300 vinyl ester resin

It should be kept in the original packaging at a temperature of no more than 20 degrees Celsius in a clean and dry environment.

Avoid exposure to direct sunlight.

The product is flammable and should be kept away from flame.

Packing

This product is available in 18 kg packages.

Durability

Ilkester vinyl ester resin has an expiration date of up to 6 months from the date of manufacture if properly stored.