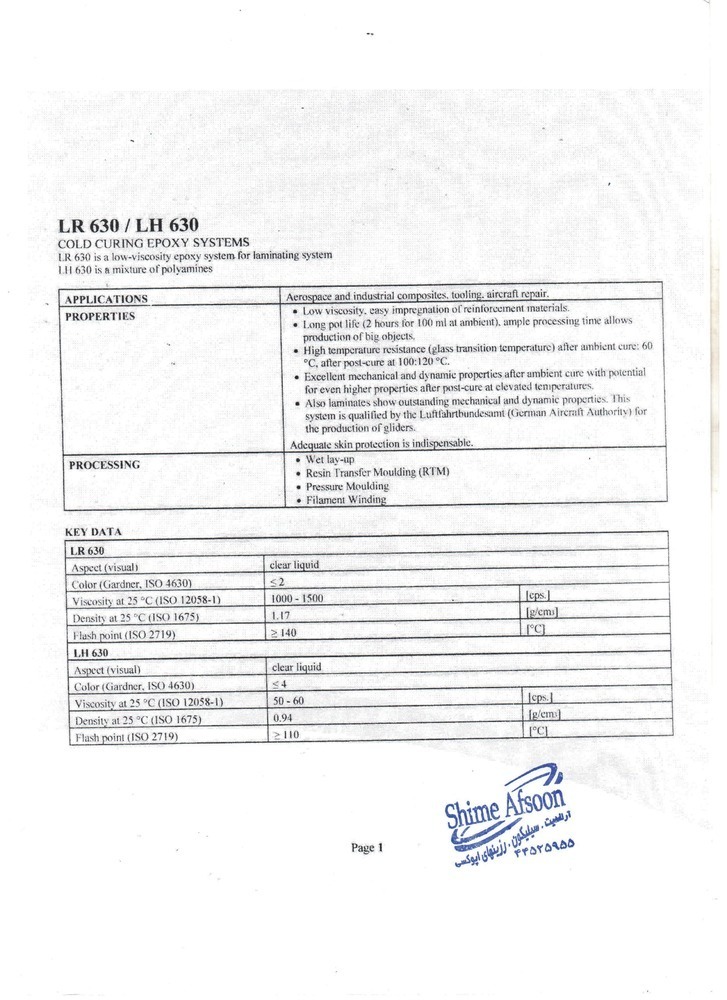

Introduction of LR630 epoxy resin

LR630 epoxy resin, which is equivalent to code LY5052 and is combined with 30% hardener H630, is one of the most widely used thermosetting layering systems. This epoxy resin with a mixed viscosity of less than 1000 centipoise is used in sensitive industries such as aerospace, automotive and marine. The outstanding features of this resin make it a suitable alternative to other synthetic resins.

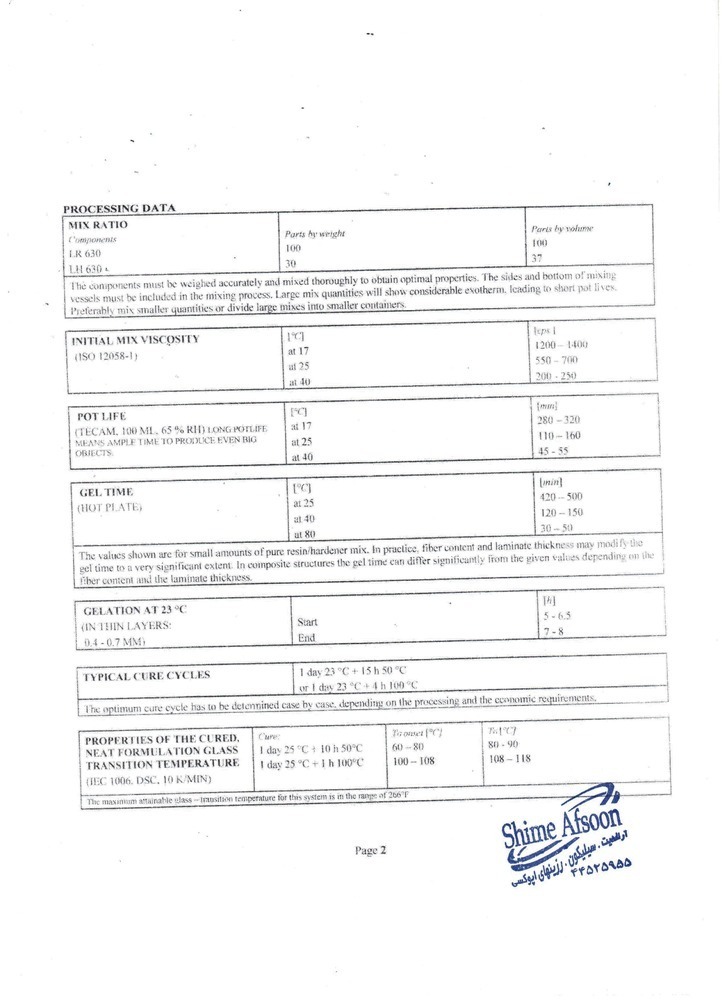

Composition ratio

Composition ratio: 20 kilos of resin + 6 kilos of hardener

Temperature tolerance of 120 degrees

Properties and characteristics of LR630 resin

LR630 resin is an epoxy type and has anti-scratch properties, high strength and resistance to heat and chemicals. This two-part system consists of resin and hardener (curing agent), which chemical reaction occurs with their combination and a hard and durable form is created.

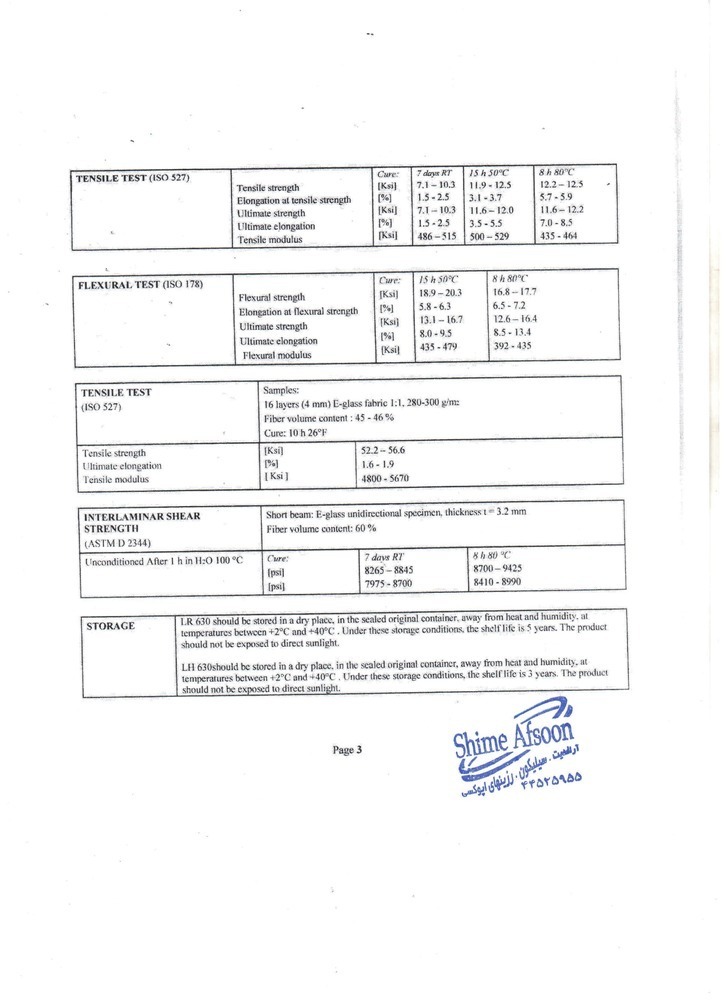

High strength

One of the distinctive features of LR630 resin is its high strength. Its very ideal tensile strength and flexural strength make this resin the right choice for applications that require strength and durability; Especially in the aviation and marine industries.

Toughness

Toughness is another important advantage of this resin. The ability to withstand sudden impacts without breaking or cracking makes it suitable for applications that require impact resistance. Making car bumpers and sports equipment are examples of the applications of this feature.

Chemical resistance

Another outstanding feature of the LR630 epoxy system is its high resistance to a wide range of chemicals, including all types of acids, bases, and solvents. This feature increases its efficiency in different industrial environments.

Various applications of LR630 resin

Due to its unique physical properties, LR630 resin is used in the production of various industrial parts such as:

– Car parts: used in making internal parts of cars that require high strength.

– Aviation industry: to produce parts resistant to harsh weather conditions.

– Electronic equipment: providing the necessary protection for sensitive electrical components.

It is widely used in the aviation industry of the country for gluing composite to composite, composite to metal, metal to metal, aluminum to aluminum, metal to wood.

Finally, LR630 epoxy resin is an excellent choice for projects that require high quality, long-term durability and reliable performance.