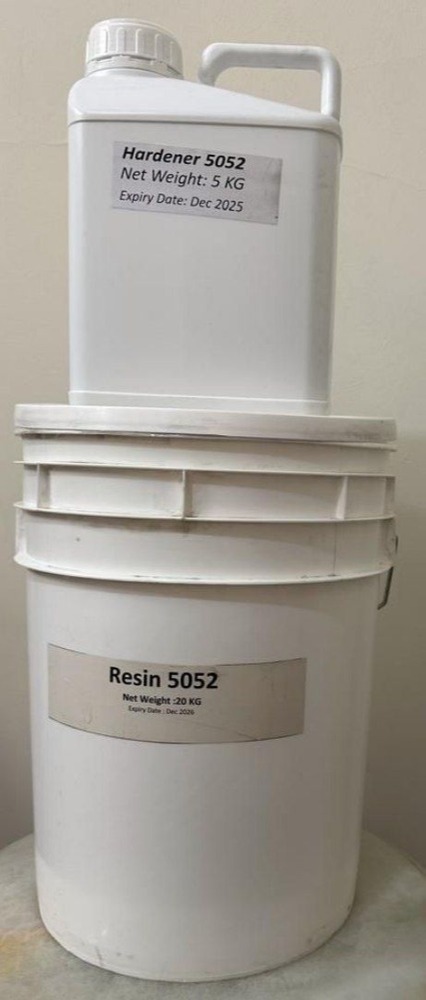

Introduction of layering epoxy resin 5052

Layering Epoxy Resin 5052 is a low viscosity epoxy resin for use with Arador 5052 (HY5052). Epoxy layering resin 5052 is widely used in aerospace and industrial composites, instrument making, aircraft repair.

Specifications

1.Low viscosity, easy saturation of reinforcing materials

2.Long life (2 hours for 100 ml in environment)

3.Resistance to high temperature after curing in the environment

4.Excellent mechanical and dynamic properties after curing at ambient with potential for even higher properties after curing at elevated temperatures.

5.Also, laminates show outstanding mechanical and dynamic properties.

Application of layering epoxy resin 5052

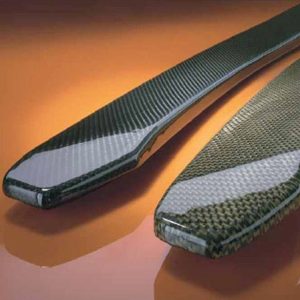

1.Suitable for industrial aerospace composites, tools and aircraft repairs

2.Special for layering

3.Laminate with glass fibers

4.Kevlar

5.Carbon, which is used in the aviation industry, has a very high resistance.

How to use epoxy resin 5052

Mixing ratio: Mix 1 kilo of epoxy resin 5052 with 380 grams of hardener 5052.

This Turkish epoxy resin is equivalent to German Hansmann epoxy 5052 and has a temperature tolerance of TG = 150 degrees.

Technical specification table

Appearance properties:

Appearance=Colorless

Physical properties

Density=1.17 g/ml

Viscosity=1500 – 3000cP For resin and hardener mixture at 25°C

Heat Deflection temperature 140> ºC

- epoxy resin ly x

- epoxy resin ly ari x

- epoxy resin ly x

- epoxy resin ly air x