50% Transparent Ketone Hardener IK-205

50% Transparent Ketone Hardener is part of special types of mixtures. In some mixtures, a hardener is used to increase the flexibility of the mixture after hardening. In other mixes, 50% Transparent Ketone Hardener is used as a curing component. A hardener can be a reactant or a catalyst in the chemical reaction that occurs during the mixing process.

Without hardeners, epoxies do not achieve the remarkable mechanical and chemical properties that they do with hardeners. The best type of hardener must be selected to ensure that the epoxy mixture meets the application requirements. You should always research the resin and hardener to ensure that the final epoxy mixture performs satisfactorily. Common examples of epoxy hardeners are anhydride-based, amine-based, polyamide, aliphatic, and cycloaliphatic.

50% Transparent Ketone Hardener are used to cure epoxy resins. However, adding a hardener to the epoxy resin may not cause the epoxy mixture to cure quickly enough. In this case, another hardener may be needed. Hardeners with special additives can also be used. These hardener additives act as catalysts that speed up the curing process.

Hardener is also used to repair epoxy resins. However, adding a hardener to the epoxy resin may not cause the epoxy mixture to cure sufficiently and quickly. In this case, another hardener may be needed.

– Hardener can also be used with special additives. These additives can act as catalysts and accelerate the healing process. Hardener is used in epoxies for construction, where work is done at low temperatures and high humidity due to its good chemical resistance.

– These compounds are used to protect epoxy floors and to repair all liquid epoxy resins and their compounds, as well as sealants.

This type of hardeners (Ketone) is used in construction in two ways; First form: It is used as a reactive component and hardener in two-component resin products such as epoxies, silicones (silicone hardener), polyurethanes and polyureas. And in the second case, powder or liquid hardener can be used on surfaces such as the floors of parking lots and warehouses because it increases their surface resistance.

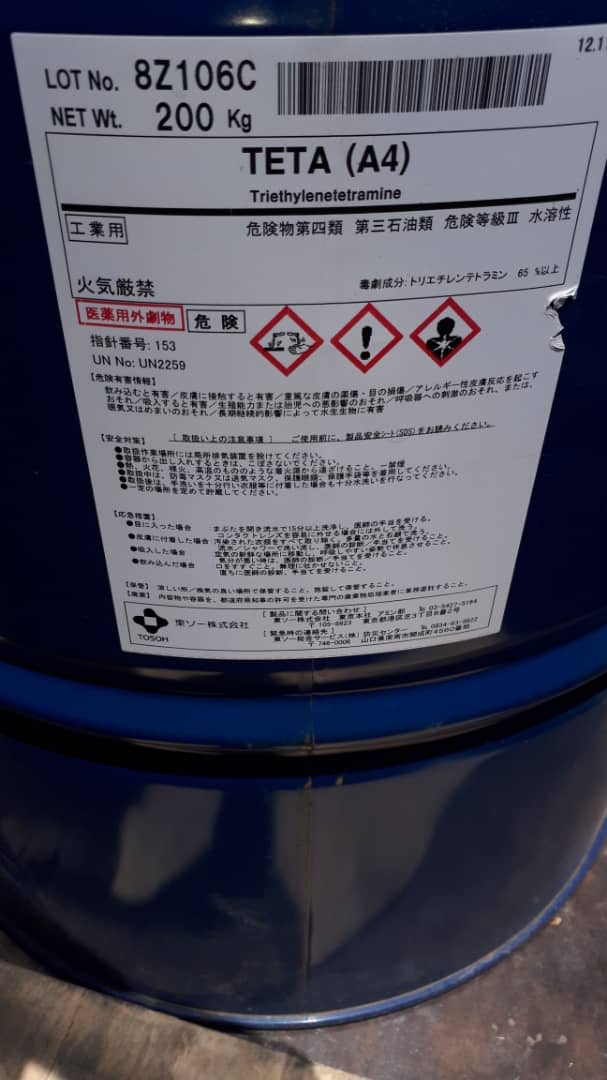

The best replacement for hardner f205 hardner ik-205

Hardeners are an important part of resins, so that without hardeners, epoxy resin will never achieve impressive mechanical and chemical properties. 50% Transparent Hardener IK-205 Iran Ketone is the best substitute for hardener f205 product. To buy 50% Transparent Ketone Hardener, you can contact the sales experts of “ShimiAfsoon” and inquire about the price of IK-205 hardener.

Properties of 50% Transparent Hardener IK-205

– Integrated coating with high transparency

– Fully fluid (low density)

– Creating mortar and lining resistant to chemicals

– Quick curing at room temperature

– Easy molding

– Decorative flooring with high alignment

– Non-toxic and solvent-free

– High shelf life and proper gelling time to remove possible foreign particles introduced into the system

– Less sensitive to ambient humidity

– Very little shrinkage

– High impact resistance

– Anti-wear

– Minimal colour change over time

– Crystallization time 12 hours

– No pungent smell of ammonia

– Resin curing mechanism

In order to reach a high molecular weight from a low molecular weight, epoxy resins must be converted into a polymer due to heat or a hardener, which is called resin curing.

Advantages of buying 50% Transparent Ketone Hardener IK-205

Among the obvious advantages of hardener F205, we can mention the characteristic of maintaining the mechanical characteristics and chemical properties of these materials in the vicinity of chemical corrosive environments and wet substrates. This advantage, along with the ability to withstand high temperatures by the corresponding hardener, has led to the widespread use of this hardener in various industrial fields.

Among the best features of this f205 hardener, the following can be mentioned:

– High chemical resistance

– Temperature resistance

– Excellent mechanical performance

– Optimal Viscosity

– Resistant to petroleum derivatives

– Stable mechanical properties over time

– Excellent adhesion to all types of surfaces

– Long usage time at ambient temperature

Application of Hardener F205 (50% Transparent Hardener IK-205)

Sales of hardener F205 are used in various areas of use. Among the applications of the desired hardener in combination with resin, the following can be mentioned;

– Floor coverings in corrosive environments

– Platforms and environments exposed to petrochemical derivatives

– Implementation in chemical environments

– Use in coastal projects and ports exposed to moisture with high salt percentage

– Solvent-free coatings

– Covering all types of transmission pipes

“ShimiAfsoon” is one of the best sellers of Ketone in Iran

Iran Ketone Industrial Production Company, as the first producer of polyester resin in Iran (hardener 50% transparent), started operating in 1354 under the license of Holz, Germany, and is currently operating as the largest resin producer in Iran.

In recent years, this production unit has expanded its range of products and added amino resins, alkyd and acrylic resins to its collection.

“ShimiAfsoon” has Iran Ketone sales representative (Iran Ketone hardener representative) and you can safely buy Iran Keeton hardener product directly from this company.