What is needle glass fiber?

Needle glass fiber is a type of synthetic fiber that is produced from glass. These fibers are characterized by a relatively long length that ranges from a few millimeters to a few centimeters and a very small diameter that reaches a few micrometers. Needle glass fibers are made of silicate glass and are used in many different industries and applications due to their special characteristics.

They have high resistance to heat, fracture and chemical changes and can be used in thermal insulation, strengthening materials, producing composites and electronic industries.

There are different types of glass fibers, of which needle glass fibers are one of the most widely used. Needle fibers are very popular in the industry due to their structure, type of texture and surface tension. If we have a general view of needle fibers, we can say that they are produced from glass and raw and accessible materials.

Forms of needle glass fiber:

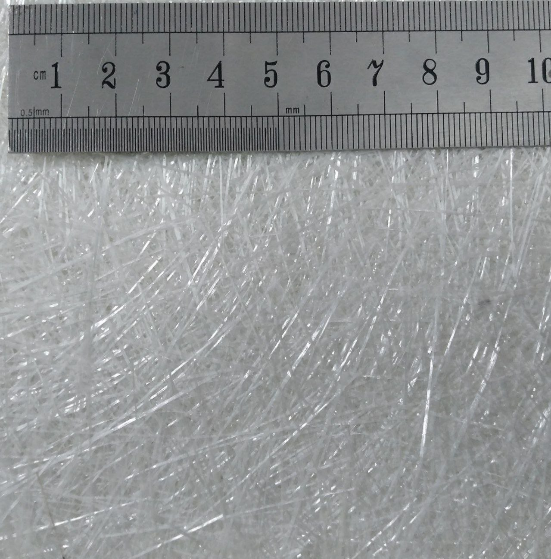

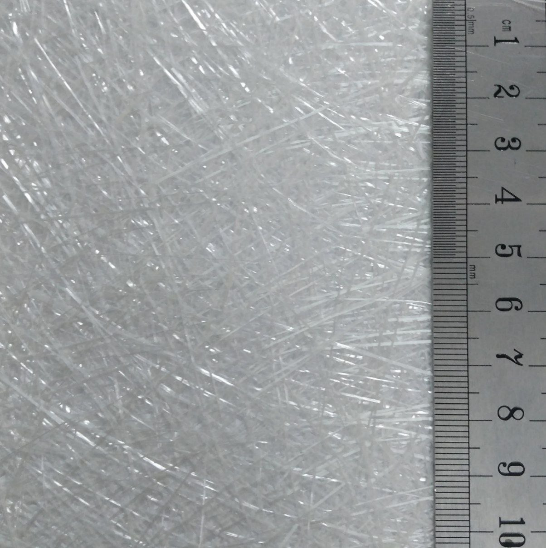

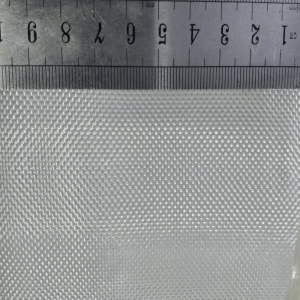

Oil glass fibers (in the form of soft sheets)

Powder glass fibers (in the form of dry sheets)

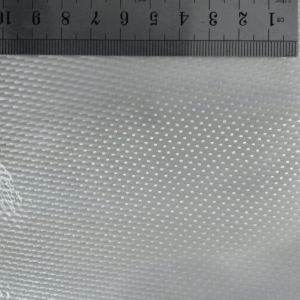

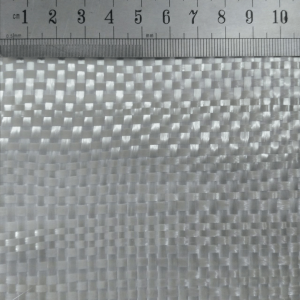

Wicker glass fibers (in the form of vertical and horizontal woven sheets)

Chopped glass fibers (chopped)

roving glass fibers (in the form of threads)

Types of needle fibers

Needle glass fibers are very popular in the composite industry. There are different types of needle fibers which are used in different cases according to the chemical percentage in which they are combined and produced.

E-Glass needle fibers

E-GLASS, as derived from the word Electrical, is a type of electrical insulating fiber. The most common fiber that can be found in the market is this type of needle fiber. Needle glass fibers have good flexibility, which, along with electrical insulation properties, has led to the use of E-Glass in the manufacture of electronic components.

The price of E-glass needle fibers is cheaper than other fibers because it has a large scale production.

C-Glass needle fibers

C-GLASS, as derived from the word Chemical, has good chemical resistance. Therefore, it is expected to be used in products that need to be highly resistant to water and chemicals. Among the cases where C-Glass needle glass fibers are used, we can mention the securing of water tanks and pipes, composite industries, and FRP, which is used as the first layer on the part surface.

Because these parts must be resistant to corrosion and destruction against chemicals.

S-Glass needle fibers

S-GLASS, as derived from the word Strength, has high mechanical resistance. This type of needle fiber is mostly used in the aerospace industry. Because the high-to-low modulus ratio is very important in missiles and certainly in airplanes.

During the production of s-glass needle fibers, a special quality must be observed, and this has made the price of S-glass needle glass fibers more expensive than other fibers.

A-Glass needle fibers

A-Glass, as derived from the word Alkali, has good acid and alkali resistance. For the production of a-glass needle fibers, materials with a high percentage of alkali are used so that this type of fiber is resistant in acidic environments. Of course, the production of these fibers has been stopped.

D-Glass needle fibers

D-Glass, as derived from the word Dielectric, has a high dielectric constant. This type of needle glass fiber has electrical applications.

ECR-Glass needle fibers

ECR-Glass is a fiber with high corrosion resistance, which is taken from the term Extra Corrosion Resistance. It can almost be said that it provides a set of suitable properties of type E and C, in addition to having more suitable dielectric properties, i.e. both chemical resistance and electrical conductivity, and also because it does not contain boron, it has been considered as suitable for the environment.

Applications of needle glass fibers

Glass fiber felt (needle glass felt) is used to make composite molds and strengthen the parts. These fibers are scattered and completely irregularly arranged in random directions. Therefore, they give strength to the parts in all directions. It is used in the construction of boats and barges, tubs, panels, etc.

Glass fibers are very thin strands of glass with a constant diameter (about 5 to 25 microns) and unlimited length. The difference between glass fibers and glass wool is that the diameter of the threads in glass wool is non-uniform and its length is limited. Also, in the glass wool production process, due to the difference in the type of cooling, the glass structure is fragile.

The difference is that glass fibers are used to increase tensile strength and strengthen composites, but glass wool is used as thermal insulation. Of course, the use of glass fibers as thermal insulation is also popular.

Glass fiber is the most famous reinforcement used in the composite industry and there are different types of it commercially. The chemical compositions of these fibers are different and each one is suitable for a specific application. Almost 90% of the fibers used in engineering composites are glass fibers.

Glass fiber has good strength and hardness, maintains its mechanical properties at high temperatures, has good moisture and corrosion resistance.

Due to its excellent elasticity, low density, resistance to thermal shocks, low price and electrical insulation, glass fibers are used in the following cases: insulation, electrical and sound industries, sports industries, aerospace industries, automobile manufacturing, construction of wind power plants, Shipbuilding, military industries, construction and chemical industries, etc.

These fibers are usually composed of 50 to 70% silica and a smaller percentage of several different types of oxides. These fibers are colorless but appear white due to refraction of light. The most widely used type of these fibers is type E, which is almost 99% of the produced fibers of this type.

The structure of these fibers is a three-dimensional network of silicon, oxygen and other atoms that are irregularly placed together, so they have an amorphous (non-crystalline) structure. Types of available forms of glass fibers: yarn-filament-bidirectional fabric-needle glass fiber and three-dimensional texture.

The difference between powder and oil fibers:

These fibers are generally both used for reinforcement in composites, with the difference that powder fibers are more effective in spreading glass particles in the environment than oil fibers and have a lower price than oil fibers. And also, oil fibers are more economical than powder fibers in terms of resin consumption.

Grammage of needle glass fibers:

In the Iranian market, according to the customers’ use, needle fibers with 225, 300, and 450 grams are usually used, which means that if, for example, a 1 meter roll of fibers is opened 225 gram fibers will weigh 225 grams in 1 meter.

The weight of needle glass fibers:

Between 30 and 40 kilos are offered in the market according to the production company.

Applications of needle glass fibers

- Increasing tensile and surface resistance of construction materials

- Used as a corrosion inhibitor in the chemical industry

- Increasing the strength of concrete and other structural adhesives

- Surface repair of concrete and its cracks

- Helping to increase the resistance of the building against earthquakes

- Used as thermal, moisture and sound insulation

- Application in industries such as making household appliances, sports equipment, making artificial body parts, automobiles

Among the applications of glass fibers, we can mention the construction industry, such that by combining these fibers with concrete and cement, very strong fibers are prepared. These fibers are also used in the automotive industry to reinforce rubber seat belts, to make cylinder heads, clutch discs and brake pads.

Glass fibers are used in the beverage industry, chemical industry, cooling towers, docks, food processing, metals and mines, aquariums, power generation industry, pulp and paper industry, automotive industry, aerospace and defense.

Glass fibers play a significant role in strengthening walls, columns and beams. In addition, glass fibers can be used in electrical industries, sanitary ware, marine industries and other uses. Glass composites are widely used in strengthening reinforced concrete and brick buildings and increase the strength and ductility of columns and walls to a significant amount.

Glass fibers increase the life of the structure and when the use of the structure is changed or the loads on it are increased, they have the ability to significantly strengthen the structure. Also, one of the materials that can replace steel in reinforced concrete is glass fiber.

Reinforcing concrete with glass fiber instead of rebar reduces the weight of concrete and completely eliminates damage caused by corrosion and erosion of steel.

- Electrical uses

- fuselage

- making molding dough

- Fireproof fabrics

- Increasing the strength of concrete and other structural adhesives

- Surface repair of concrete and its cracks

- Used in industries such as manufacturing household appliances, sports equipment, manufacturing artificial body parts, automobiles, etc.

- Needle glass fiber 300

- Needle glass fiber 225

- Needle glass fiber 450

Characteristics of needle glass fibers

Chemical resistance: needle glass fibers are resistant to chemicals, and bacteria, fungi and other animals do not affect the fibers.

Moisture resistance: This fiber does not absorb moisture.

Electrical properties: Needle glass fibers are suitable for use in the manufacture of electrical components due to their insulation against electric current.

Physical properties: high modulus of elasticity and tensile strength, good flexibility.

High tensile strength and modulus

Dimensional stability: which is considered one of the important characteristics of glass fibers and does not undergo many changes under the influence of temperature, and generally has a low linear expansion coefficient.

Good chemical resistance

Good flame resistance

The high mechanical strength of fiber is such that it is said that its mechanical resistance is greater than that of steel, which makes this material a high-performance reinforcement.

Good electrical insulation- even when it has a small thickness, is good electrical insulation.

Low thermal conductivity – which has resulted in it being considered a suitable material for construction industries.

Good compatibility with organic materials: in such a way that the chopped type of these fibers can be combined with cement and create a resistant composite.

Glass fibers are highly durable so that they do not suffer from corruption and are not affected by insects and rodents.

Dielectric permeability, glass fiber is dielectric permeability, so it can be used in the construction of electromagnetic structures.

Almost 90% of the fibers used in engineering composites are glass fibers.

Glass fibers also have good strength and hardness. They maintain their mechanical properties at high temperatures.

They have good moisture and corrosion resistance and are relatively cheap. There are many types of needle glass fibers commercially available.

Needle fiber has a good resistance modulus in all directions.

For this reason, it is very widely used in the composite industry and has the highest consumption per capita among other glass fibers.

These fibers have good resistance against moisture and acid and alkali.

Suitable for polyester resins, vinyl ester, epoxy and…

Storage conditions of needle glass fiber

The product is in the form of a roll with a tube that is packed in polyethylene bags.

Needle fibers should be stored in a dry and cool place at a temperature between 10 and 35 degrees Celsius with a humidity of less than 65%. It is recommended not to store the product for more than 24 hours in an environment where the temperature is less than 10 degrees, and in order to prevent moisture absorption, do not open the package until use.

Keep them away from sunlight and avoid direct moisture contact with the fibers and keep them in a covered environment.

Durability of needle glass fibers

The shelf life of the product is 12 months.

Needle glass fiber packaging

30 kg (one roll)