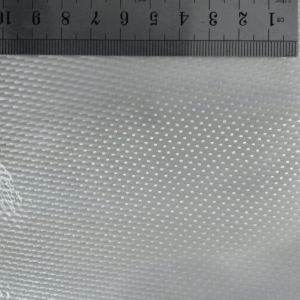

Introducing 100 grams plain wicker fibers

100 gram glass fiber with its fine texture is used specifically in the aerospace industry and making composite parts with a focus on weight reduction. These fabrics are also used to cover unilith models.

Due to the high wettability of these fibers, it is recommended to vacuum the part after using them. 100 gram glass fiber is especially used in the production of various types of drones and various components of the aviation industry, such as wings and bodies.

In making unilith models, first the foam is carved with a CNC machine and then several layers of epoxy resin are applied on it to strengthen the surface of the foam. After that, one or two layers of 48 or 100 gram glass fibers are added as a surface coating. This layer prevents the foam from being eaten by the polyester putty (stone putty) in the next steps. Also, stone putty adheres well to this layer.

Therefore, one of the main applications of 100g-Plain glass fibers is in the preparation of unilith models for mold making. It is highly recommended that the parts produced with this fabric be vacuum bagged.

Applications of 100 garms plain wicker fibers

Woven glass fibers are used to make mechanical parts, strength to achieve the best results in polyester and vinyl ester and other high performance resin systems. This product is widely used in the production of boats, containers, airplanes, car parts, interior decoration, sports equipment, corrosion-resistant tanks, wind turbines and other parts, and plays a significant role in increasing the mechanical strength (longitudinal and transverse) of the parts. Composite plays.

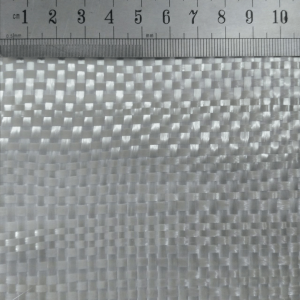

100 grams plain A glass wicker fibers

100 gram plainA wicker fiber is suitable for making composite air parts, model airplanes, airplane repairs and parts that require lightness along with high resistance.

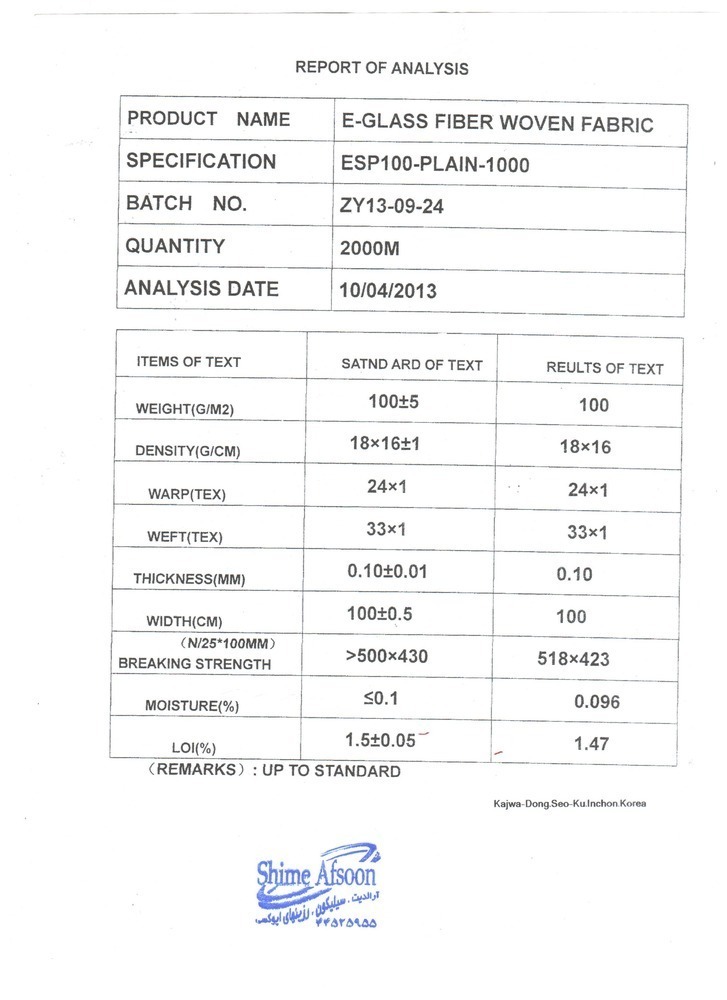

Characteristics of 100 grams plain A glass wicker fibers

High mechanical resistanceHigh mechanical resistance

Excellent dimensional stability

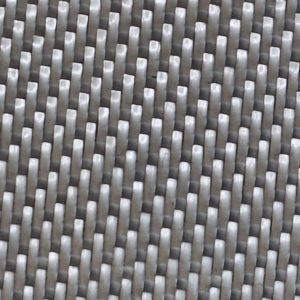

Uniformity in texture

It has many pores and facilitates the absorption of resin and fibers with very small pores

Wavy and flexible structure for easy application

Top glass cover

The texture pattern is a combination of the best types of fibers

Engineered warp and twist of fibers

High mechanical resistance

High resistance to moisture

In all types of plain, satin, etc. fabrics, there are two-way fibers with very high resistance, whose fibers are placed in two perpendicular directions, 0 degrees and 90 degrees. Among the most important features of this category of fibers, in addition to their high tensile strength, we can mention light weight and resistance to all kinds of environmental conditions and acidic environments.

Today, bidirectional fibers are used in various fields and industries, such as the manufacture of automobile and aircraft parts, the manufacture of sports equipment, the construction of ship hulls, etc., but the most important place of consumption and application of bidirectional glass fibers can be mentioned in the strengthening and sealing industry, which It is used for retrofitting buildings and industrial structures, retrofitting bridges, retrofitting pipes and steel and concrete tanks, seismic retrofitting of buildings, etc.

Due to its resistance to corrosive factors, two-way glass fibers are widely used as a protective coating in various industries. Also, due to the electrical insulation of these fibers, they are used in various fields that require thermal insulation with high resistance and durability.

Storage conditions for plain wicker fibers

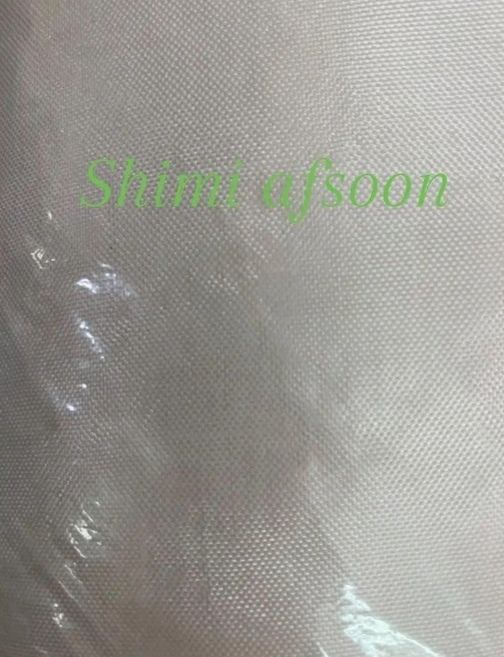

Plain wicker fibers are in the form of rolls with tubes, which are packed in polyethylene bags.

Wicker fibers should be stored in a dry and cool place at a temperature between 10 and 35 degrees Celsius with less than 65% humidity. It is recommended not to store the product for more than 24 hours in an environment where the temperature is less than 10 degrees, and in order to prevent moisture absorption, do not open the package until use.

Keep away from sunlight and avoid direct moisture contact with fibers and keep them in a covered environment.

Durability of plain wicker fibers

The product’s storage period is 12 months.

plain wicker fiber packaging

40 kg equivalent to 200 meters (one roll)

datasheet PLAIN[/caption]

datasheet PLAIN[/caption]