Introduction of Perox A60

Introduction of proxies

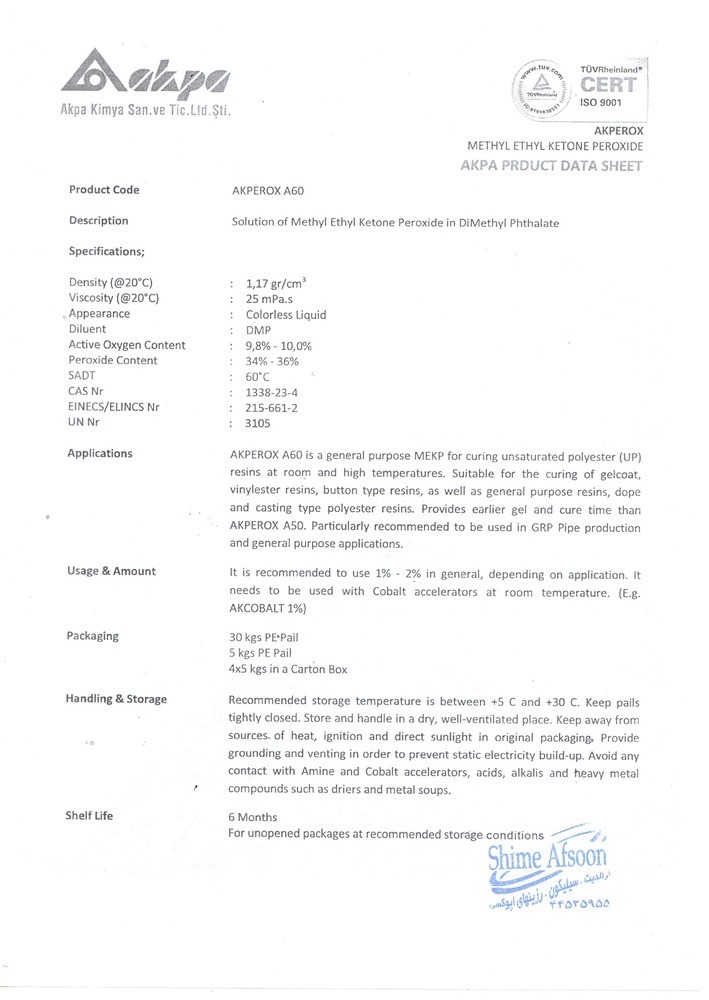

Methyl ethyl ketone peroxide (acid peroxide) is the most common peroxide that is used and the range and amount of this peroxide that is added to the resin is 2%. For resins, they should be used with 10% cobalt and, if needed, with amines or inhibitors.

Peroxide acid is used as a desiccant in the fiberglass industry. The combination of acid and cobalt with resin has a certain amount, which is one of the important requirements in this work. This product has different gel times compared to the percentages of its different types.

Application of Perox A60

Polyester dryer

In the glass, plastic and fiberglass industry, it is used as a curing agent.

It is used as a hardening agent in the production of petrochemical resins and plastics.

A60 acid is suitable for processing unsaturated polyester resins (UP) in room and high temperature. It is suitable for refining gelcoat, vinyl ester resins, as well as resins for general use, polyester resins of plaster type and casting. It is recommended to be used in the production of GRP pipes and for general purposes.

A60 acid is one of the most important and practical organic peroxides and is mainly used in the industry as a catalyst in the production and curing of unsaturated polyester resins, vinyl ester, fiberglass, plastics and in casting.

Perox A60 storage conditions and safety issues

It should be kept between +5°C and +30°C. Store in the original packaging in a dry and well-ventilated place away from heat, ignition and direct sunlight. In order to prevent static electricity, create ground insulation and ventilation. Avoid any contact with amine and cobalt accelerators, acids, alkalis and heavy metal compounds such as dryers, etc.

As a result of heat and spark, it catches fire and immediately decomposes and burns the skin severely and causes blindness due to contact with the eyes. The consumption amount for polyester resin and vinyl ester depends on the environmental conditions and is 2% in normal conditions.

Durability of Perox A60

6 months for unopened packages under recommended storage conditions

Packaging

30 kg

A[/caption]

A[/caption]