What is Vacuum tape?

Vacuum tape is a type of adhesive tape that is used in the vacuum bag or injection process. Vacuum tapes are usually made of flexible and resistant materials and have the ability to work under pressure conditions caused by the vacuum process. In vacuum bag or infusion processes, the vacuum tape is used as a finishing element.

This tape is used to block and narrow the space between the vacuum film and the composite parts so that the vacuum pressure is maintained and the resin material is evenly and optimally distributed in the parts.

Vacuum tapes can also be used to stabilize parts and materials within the vacuum film. By using this adhesive tape, different parts and materials are placed in the right place and their movement during the vacuum process is reduced.

Features and application of flood tape

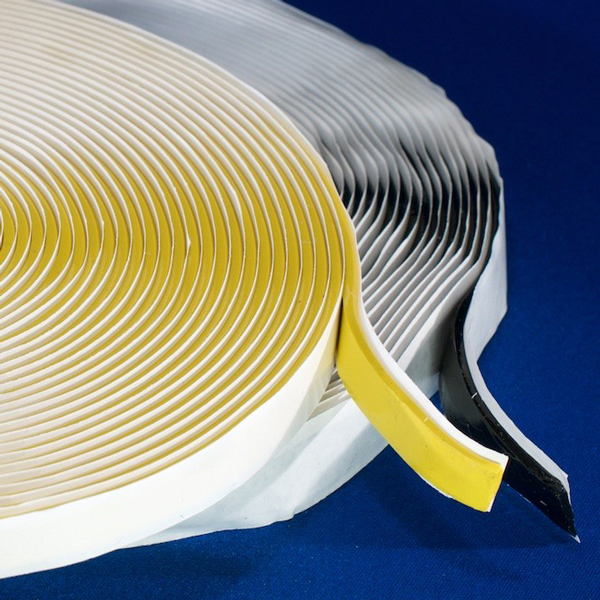

As mentioned, vacuum tapes are one of the efficient solutions in sealing and sealing different parts. These tapes are divided into two categories, normal and thermal, each with its own features and applications.

Normal vacuum tape, using adhesive and flexible materials, is used to block and seal the space between parts. This type of vacuum tape is placed on the surface in an integrated manner without the need for heat application and is able to prevent the penetration of moisture, air and other undesirable substances.

Thermal vacuum tape, in addition to the features of a normal vacuum tape, has the ability to activate and bake at higher temperatures. By applying the right heat, this vacuum tape is activated and seals the seams and connections firmly and permanently.

This thermal feature allows thermal vacuum tape to work well in processes that require high temperatures and baking, and gives more strength and adhesion to the seams.

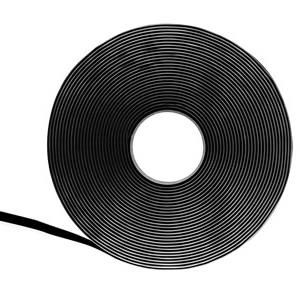

Vacuum tapes can be presented in black or other colors, depending on the need and the place of use. These strips are used as a basic element in sealing and vacuum sealing processes due to their flexibility and resistance and can be used in many industries including composites, automotive, construction and electronics.

Application of vacuum tape in composite

Nylon vacuum is used to make composite parts using the vacuum bag method. In this method, the resin and fibers are placed inside the vacuum bag and the bag is completely closed and sealed using a vacuum tape. Then, using a vacuum pump, the air inside the bag is absorbed and the resin and fibers are pressurized. This method causes the release of excess air and increases the percentage of fibers. Also, because the resin and fibers are confined by the vacuum bag in all directions, the final piece will be smooth and uniform after leaving the vacuum bag.

Vacuum tape packaging

Now you can get high quality flood tape from the reliable Shimi Afsoon company. As one of the producers of composite and fiberglass raw materials, Shimi Afsoon offers high-standard products with a commitment to superior quality and performance. Black vacuum tape with a length of 15 meters and yellow vacuum tape with a length of 7.5 meters are among the available products. By using this vacuum tape, you will be able to achieve complete and reliable sealing in composite and fiberglass manufacturing processes.