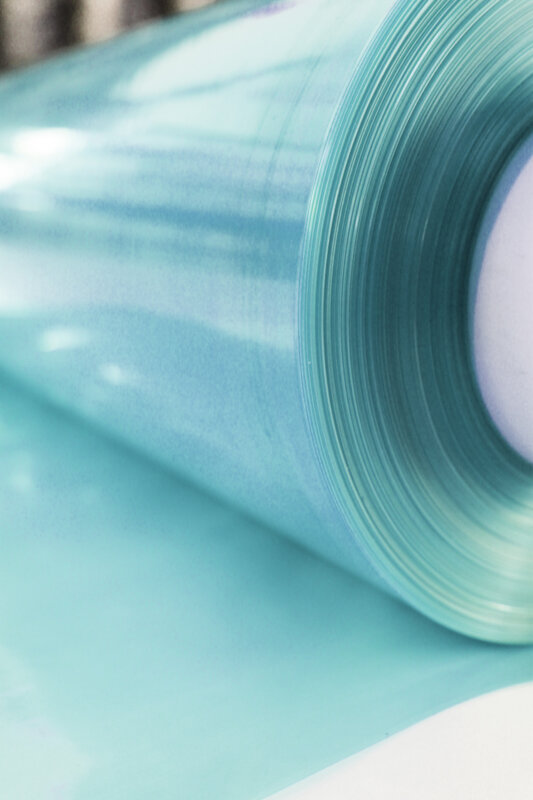

Thermal vacuum nylon

Thermal vacuum nylon (vacuum plastic) is a version of thermoforming in which a sheet of plastic is heated to forming temperature, stretched over a single-layer die, and placed against the die by vacuum. This process can be used to turn plastic into permanent objects such as signposts and protective covers.

Thermal vacuum nylon is one of the most widely used nylons in manufacturing and packaging industries. Thermal vacuum plastic or so-called shearing nylons are a type of plastic nylon that shrinks in contact with heat, which is called a vacuum. This nylon is one of the most suitable plastics for packaging products.

Buying thermal vacuum nylon from Shimi Afsoon

Thermal vacuum nylon is one of the essentials of packaging, the use of which both adds beauty to the product packaging and protects the products. You can get special privileges by buying nylon vacuum rolls from the direct manufacturer, Shimi Afsoon:

- High quality manufacturer

- Not having an unpleasant smell when shearing

- High quality, good quality

Common dimensions of thermal vacuum nylon

Thermal vacuum nylon is usually produced in different sizes and dimensions, lengths and widths at Shimi Afsoon Company. The more layers of thermal vacuum plastic, the thicker and stronger these nylons will be and can be used in more sensitive work.

Usually, the thickness of nylon vacuum varies from about 30 microns to 200 microns. Usually, single-layer thermal vacuum plastic is very thin, and to use it, it is better to wrap this type of plastic several times.

Reasons for using thermal plastic shearing

The packaging material of many products is cardboard, paper or wood. Although the weight of such packages is light and reduces the cost of handling, it faces problems during storage; One of these problems is that they are easily damped and blown.

Because the product may be opened and damaged during transportation, to prevent such cases and to ensure the health of the product packaging, the product can be packed with thermal plastic shearing to safely store and move the products.

Application of thermal vacuum nylon

Thermal vacuum plastic has many applications in many different industries, the most important applications in which this type of thermal nylon is used are:

- Home Appliances

- Car spare parts

- Soft drinks and mineral water

- Building facade stones

- Packaging of ceramic tiles

- Food boxes such as tuna

- Salad packaging

- Building facade stones

And…

There are different types of thermal vacuum nylon that we will examine.

Food grade vacuum nylon

One of the best types of food packaging that needs a long shelf life is the use of nylon vacuum food rolls, which, by completely evacuating the air from the inside of the package, increases the freshness of the product and prevents its spoilage. You can also use vacuum bags at home.

Nylon vacuum bag

One of the most widely used types of thermal vacuum plastic is the vacuum bag. In this type of nylon vacuum roll, you only need to send the dimensions of the bag to the production factory.

Industrial vacuum nylon

In this type of packaging, which is used for wholesale distribution in stores, it needs a stylish packaging with printing or affixing a label.

Thermal vacuum plastic for clothing and bedding

There are many different kinds of vacuum bags for clothes, blankets, and bedclothes in the market. Shimi Afsoon always tries to prepare for sale one of the highest quality samples that can be offered.

Thermal vacuum plastic for clothes and bedding are nylon bags of special PVC that are used for clothes or blankets and bedding and have several uses.

- To reduce the volume of clothes for better placement in the suitcase for traveling and to reduce the volume of blankets and bedding for placement in the closet.

- To protect from getting dirty or rotting, dust, willow, moisture, etc., which will not be damaged as a result.

Vacuum bags are available in different sizes, for example, smaller sizes are used to fit in luggage and larger sizes are used for bedding.

Each vacuum bag can be used many times and is not disposable and will not crack or crumble over time.

It is enough to drain (suction) the air inside the vacuum bag through the regular pipe of the vacuum cleaner through the special valve on which the contract is placed and then close the lid to see a 75% reduction in clothes or blankets and mattresses inside.

Production of heat shearing plastic

Shimi Afsoon Company is able to produce all kinds of nylon shearing (thermal) rolls in all sizes and thicknesses with unlimited production.

After nylon vacuum production, for easier use and better transportation, the produced heat shearing plastic is rolled into a roll or film. These films are called roll-shearing packaging. It is possible to produce nylon sheeting and thermal cellophane for packaging in all dimensions and thicknesses, and there is no limit in production.

How to print on thermal vacuum nylon?

One of the main reasons for printing on thermal nylon is to make the product visible to the public. This increases the number of customers; But if high-quality printing is not done, it will make your product worthless. Printing on shearing packaging is a form of advertising. As we said, one of the most important features of thermal vacuum plastic is the ability to print images, logos, etc. on it.

This feature makes the insulated and protected package unique by these nylons. During the experiments conducted in the laboratory environment, it was proved that as the compression and swelling in the shearing process increases, the length of the shearing decreases as well. As a result, the production and printing stages of nylon shearing must be completely planned based on the customer’s information.

How does vacuum nylon work?

Usually, there are two domestic methods (vacuum plastic with a hair dryer) and industrial methods for working with thermal vacuum plastic. With these methods, by placing the nylon vacuum roll against the heat, the plastic shrinks and the product is easily packaged.

* Vacuum packaging is a cost-effective method for customized packaging of various types of products, which has an important place in the packaging industry today.

Thermal vacuum is a process for shaping thermoplastics such as PVC, HP and PET, which can be used to produce various parts such as product packaging parts.

Vacuum packaging plays an essential role in our daily life and you must have seen this type of packaging while shopping in stores and retail stores.

Features of thermal vacuum nylon packaging

- The transparency of the packaging

- High production speed

- Cost-effectiveness in terms of equipment

- Flexibility and high accuracy

- Sanitary

The transparency of the packaging: the most important advantage of nylon vacuum packaging is its transparency, the transparency of the packaging makes the product inside the package have a special effect and the customer can visually observe and check the product before buying and then proceed to purchase. This also increases product sales.

High production speed: The production speed in this process is very high and the distance between the design and the final product is also small, so with thermal vacuum nylon, the product can be packaged and presented to the market at a high speed.

Cost-effectiveness: This process is cost-effective compared to other methods, and the equipment and devices of this type of packaging are much simpler and more cost-effective than other methods (such as plastic injection).

Flexibility and Accuracy: in this process, before the production of packaging, measures such as review, design of the initial mold, testing, etc. are carried out, and then the final product is produced taking into account all the items, so this process is very flexible and the accuracy in this process is very high and The error is also very low.

Sanitary: In this process, completely hygienic materials can be used to produce food containers and food packaging.

Important points for packing using thermal vacuum nylon

- An important point in buying thermal sheeting nylon rolls is that you should buy these rolls as needed and they should not be piled on top of each other.

- Excessive heat to nylon will melt and destroy the plastic. Be sure to get enough information about the thermal range and the tool you use to heat the nylon before packing and sharing the product.

- It is suitable for equipment and heavy packing of nylons made of polyethylene.

- It is more suitable for food packaging such as fruit packaging, nylon shearing polyolefin.

- PVC nylon sheathing is cheaper and more economical, but it needs special care due to the production of toxic gases.

Maintaining the thermal vacuum roll

Due to the fact that this type of thermal vacuum plastic is very sensitive and easily deforms, important points should be taken into account in its maintenance:

Never stack nylon vacuum rolls and never buy more than you need. After these nylons are unused for a long time, the bobbin or cardboard tube inside them changes shape and also loses its properties.

Do not compress the nylon rolls in any way or stack them vertically in any way. This causes the rolls to slide and become conical.

Note that you should never expose the rolls to moisture as they are extremely vulnerable.

These nylons are sensitive to sunlight, so keep them out of the sun.

The difference between thermal shearing nylon and normal nylons

In terms of application, nylons can be classified into different types, in addition to thermal shearing nylon, normal nylon can also be mentioned.

Normal nylons are also widely used radars. These products have been used for covering and many other applications, and like nylon shearing, they have become important in many professions.

Now, if we want to examine the difference between thermal shearing nylon and normal nylons; It can be said:

Shearing nylons are sometimes used for packing heavy parts; As a result, they have more resistance and strength. Due to their thickness and normal resistance, normal nylons are mostly used to cover or pack lighter objects.

Shearing nylon can be used with a thermal vacuum device and therefore has the necessary resistance to heat, especially in higher layers. But normal nylons cannot be exposed to high heat and there is a possibility of melting. Shearing nylon is associated with the ability to print, and this feature is not seen in normal nylons.

The flexibility of thermal shearing nylon is more than the normal type of this product. Also, the price of shearing nylon compared to normal nylon, due to its features, is associated with a higher percentage, which is known by buyers.

In short, the main difference between normal nylon and shearing nylon or thermal shearing plastic is in the composition of petrochemical raw materials. The most important and obvious feature of thermal shearing plastic is their very high flexibility and high tensile strength.

The price of thermal vacuum nylon (thermal shearing plastic)

Several factors are effective in determining the price of nylon vacuum or shearing, such as: width, degree of transparency and brand of nylon. Of course, in the current economic conditions, it is very difficult to determine the price and it is not possible to consider a fixed price for this thermal vacuum nylon. For this reason, you can contact our colleagues in the sales department of Shimi Afsoon for more information.